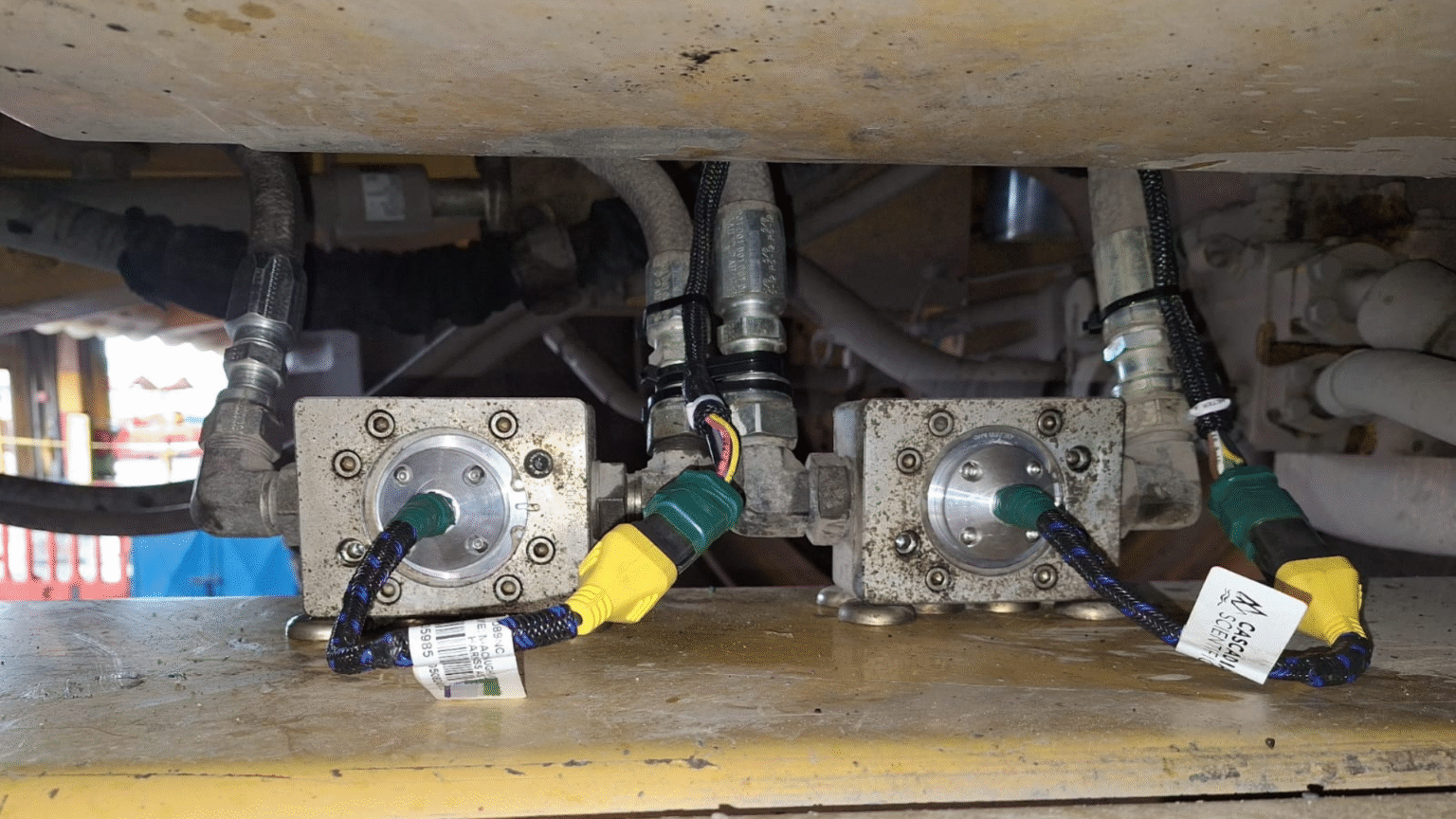

Taurus by Cascadia Scientific is a real-time monitoring solution that helps mines optimize support equipment like dozers, graders, and water trucks.

It delivers fleet-wide visibility into fuel use, location, and task efficiency, enabling reduced idling, safer operations, and smarter fleet sizing.

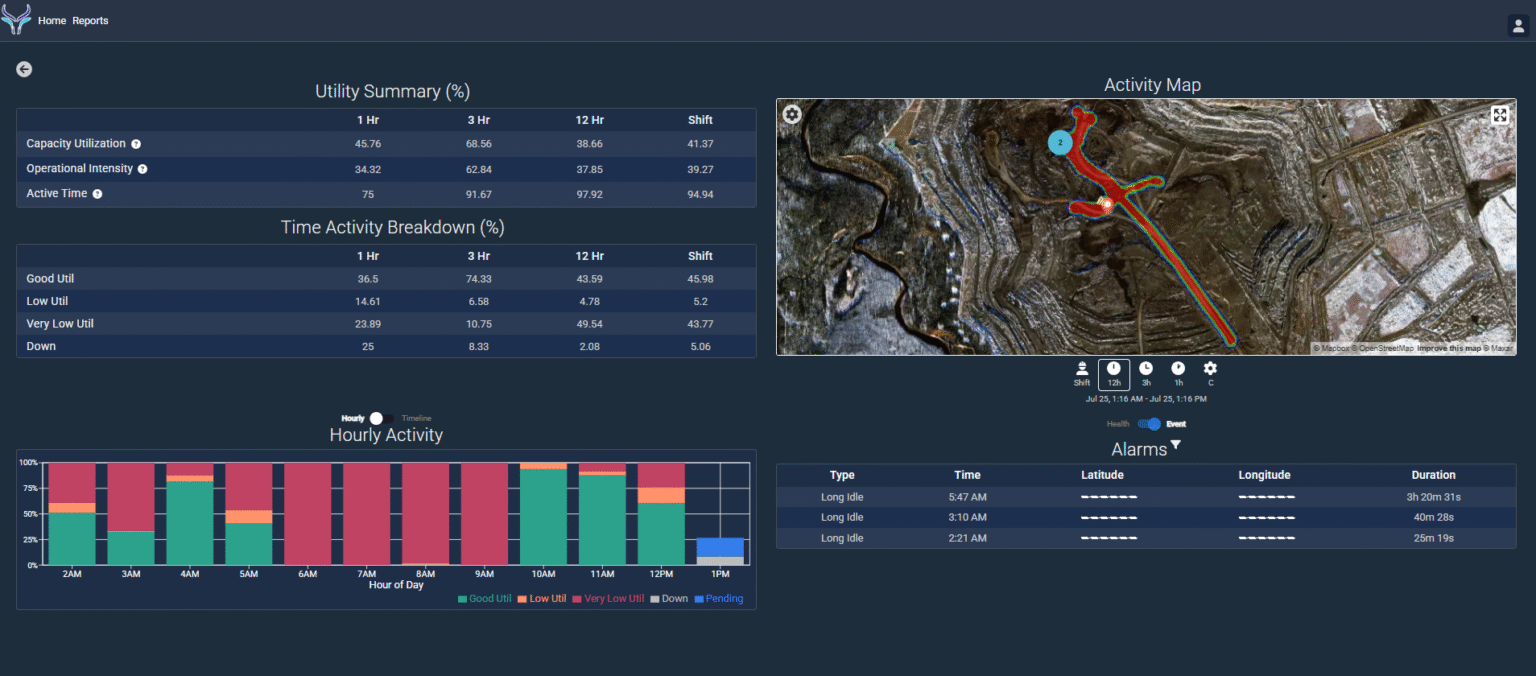

At the heart of Taurus is Capacity Utilization.

A data-driven metric that reveals how effectively machines turn uptime into productive work. Whether pushing, ripping, or cleaning, Taurus identifies underused assets, supports operator performance, and ensures every move delivers value.

Support equipment is essential to site productivity, but without data, inefficiencies go unnoticed. Taurus brings your support fleet into the digital age with:

Cost Efficiency – Avoid overinvestment by accurately sizing your fleet, ensuring optimal utilization and significant cost savings.

Real-Time Optimization – Utilize up-to-date data to adjust fleet size according to operational needs, maximizing efficiency

Operational Excellence – Enhance efficiency across dump sites and shovels, protect equipment, and maintain continuous operational flow

Taurus boosts dozer efficiency by delivering real-time insights into

capacity utilization, operational intensity, and active time.

Here’s how it drives results:

Capacity Utilization

Taurus tracks how effectively each dozer converts active time into productive work, using fuel consumption as a key indicator to identify inefficiencies and optimize deployment.

Location-Based Optimization

Real-time tracking enables strategic redeployment, improving productivity without adding new equipment.

Operational Intensity

It compares fuel burned to the dozer’s capacity, offering a clear view of performance across different machines and tasks.

Idling Alerts

Taurus tracks long idling events and provides alerts, helping supervisors reduce waste and boost operator efficiency.

Active Time & Underutilization Detection

By monitoring engine run time, Taurus flags dozers operating below 50% utilization for redeployment to high-value zones.

Reporting & Heatmaps

Shift-based reporting and heatmaps identify bottlenecks and inefficiencies, supporting continuous improvement.

Support fleet questions Taurus can answer:

With Taurus, you can:

Because productivity gains shouldn’t stop at your haul trucks. Taurus closes the data gap on your most overlooked fleet assets, reducing fuel use, improving deployment, and preventing avoidable incidents with actionable insights you can trust.

Stop guessing. Start optimizing. Taurus gives you the real-time visibility you need to reduce costs, prevent equipment damage, and make smarter decisions acrossyour support equipment.